Ore Inc. is made up of a local gang who design and develop indoor/outdoor planter boxes, outdoor furniture, and a myriad of other garden accessories. Put simply, they take pride in their work; it's obvious in every last facet of their processes and business ideals. No project too big or too small, Ore is ensuring that the efforts are conscious from start to finish. That is to say, there's multiple environmentally-friendly procedures at work here, which we love. All told, the amazing design team and skilled craftsman have managed to land on a line of products that is unique, stylish, and proudly local. We put on some sweet safety glasses and took a tour of the shop [it was impressive], then we shot a few questions their way. Oh, it's good stuff. Read on...

"We're bringing this life form to life" is something we heard a few times in the shop. What's the story on that? “Bringing this life form to life” is best described by a mantra that our powder coater, Scott, has developed: “The customer imagines it, the fabricators create it, the powder coater brings it to life.” This saying illustrates how we think about design, manufacturing, and the finishing of all of our products. From concept, to design, to fabrication, each person down here at Ore, no matter what role in the process, is intimately connected with the result.

What you've created -- and the ways in which you've implemented your life's philosophies into your business -- is impressive. How were you inspired to work this way? From the very beginning, we have always believed you could build a business around two philosophies: 1) We can design and build aesthetically-pleasing, fully-functional, high-quality products in the USA that are made from renewable, raw materials, and we can manufacture them using responsible methods that won't destroy our environment in the process. And 2) we believe we can separate ourselves from others by simply doing what we say while providing exceptional customer service. Example: we say it’s going to be a well-designed functional product, and we deliver. We say it's going to be delivered on a certain date, and it's delivered on that date. Over the last ten years, we've proven that these two simple philosophies have been a critical foundation of the growth we continue to experience.

Why is "Made in the USA" so important to you and your business? It is not some patriotic 'rah, rah, rah'. We are here, this is what we do, so why NOT have it made in the USA? We strongly believe in utilizing all of the talent and ability that exists right here in Salt Lake City. We love having the ability to walk into our shop and alter a design or fix an issue, all while creating a small economy for a terrific group of people! We are proud to say that Ore's entire line is produced -- start to finish -- in our domestic manufacturing facility at the base of the Wasatch Mountain Range in Salt Lake City, Utah.

Share a turning point in your business: 2008 was a major event for every business and individual in the US. We really learned how efficient we could become. During this process we really defined who our customers were and with that, focused primarily on servicing them exceptionally.

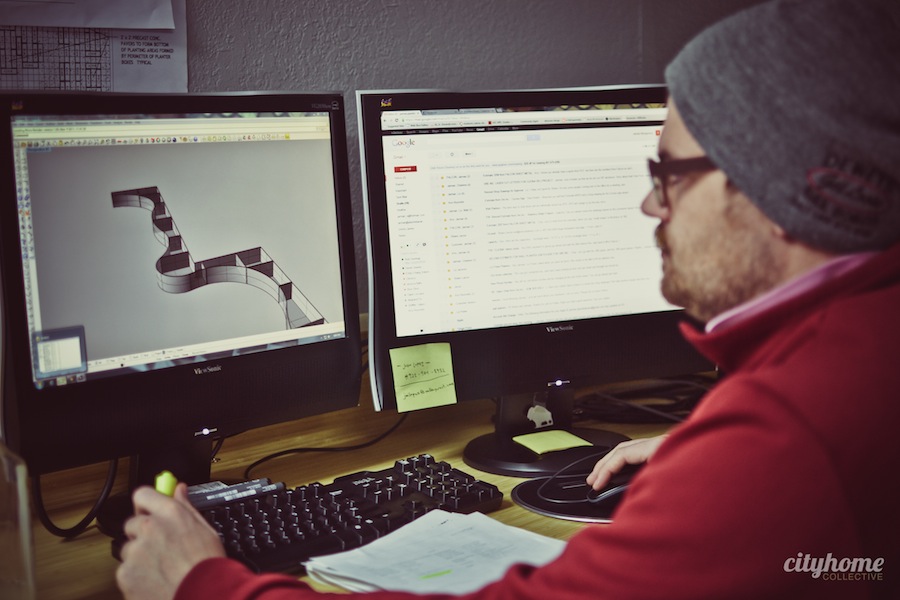

Talk a bit about JARM; how has it implemented an efficient and satisfying design strength in your business? Another service we provide here at Ore Inc. that has really made us unique in the industry is our CAD services department. We utilize the most up to date, modern, and technically-advanced 3D software providing full CAD support from conceptual drawings to shop drawings to 3D modeling. This helps support the design conversation between Ore and our customer demonstrating both our ability and willingness to collaborate at times on really complicated installations without giving up the aesthetic beauty or design quality of our product. In the beginning, we thought we would just make some "flower pots" but as it turned out, a large portion of our business is being installed on rooftop decks in major cities such as Manhattan, San Francisco, and Chicago. In some cases streets need to be closed, a permit needs to be had, and cranes are needed to lift all of the products (including the planters, soil, and petunias) to the 23rd floor of a metropolitan high-rise.It is critical that the planters fit, are delivered on time, and that in the end when the project is finished, it looks like effortless perfection. This brings me to one of our other mantras: Perfect will be good enough.

Give us an easy-ish understanding of the oxidation process you created for aluminum to look like zinc, and tell us why it's so desirable. We have had numerous customer requests for zinc or lead containers. What the customer is actually looking for is the beauty in the naturally-aging patina of these materials. Surprisingly, what most people aren’t aware of is that lead is toxic and zinc doesn't make a good material for planters because it is too soft, too expensive, and too toxic to weld. In my 25 years of experience, I have come to understand metals intimately and the way to patina different metals using methods that have been around since the Egyptians. I, too, love the look of the aged patina on zinc, so after configuring formulas for six months, I developed a patination process that oxidizes the bare, recycled aluminum we use on all of our planters. This creates an identical, ever-changing aged patina, minus the toxicity that both the lead and zinc material contain, while retaining all of the strength and integrity of the aluminum. This is a proprietary process that only Ore can provide. We really love the contrast of this old-world finish on our sleek, modern designs.

You told us a lot of the efficient and reusable steps you take in creating your product. Speak a little more to that, and tell us which procedures you're most proud of. How many aluminum cans does it take to make a 27” Aluminum cube? 1,290. That’s 107.5 12-packs. Here at Ore Inc., we actively seek ways to limit the environmental impacts of our manufacturing, packaging, shipping and administrative processes. We implement energy efficient building solutions and specify sustainable products in our facility.

The primary materials used in the manufacturing of Ore Inc. products are Aluminum, Mild Steel, Stainless Steel, Cor-Ten, Ipe, Black Locust and raised grain cedar wood. These materials are specifically chosen for their durability, their ability to withstand the rigors of outdoor environments, and because they are the worlds most recycled material and are 100% recyclable.

We have the choice to use 100% virgin aluminum, BUT, for a little more money we can buy the aluminum that has a higher recycled content which is what we choose to buy here at Ore Inc. Our mild steel contains a recycled content of 66%; approximately 60% is post-consumer material and 6% post-industrial material. An average stainless steel object is composed of about 60% recycled material of which approximately 40% originates from end-of-life products and about 60% comes from manufacturing processes.

Ore Inc. manufactures many of its designs out of wood. We employ sturdy hardwoods for exterior use that are stable, resistant to insects and rot, are difficult to carve into, and do not require a protective finish. All Ore Inc. wood products utilize wood harvested from sustainable-managed forests. As part of our commitment to sustainable forestry, Ore Inc. shall not use illegally-harvested wood, wood from genetically-modified trees, or wood harvested from forest areas where traditional or civil rights are violated.

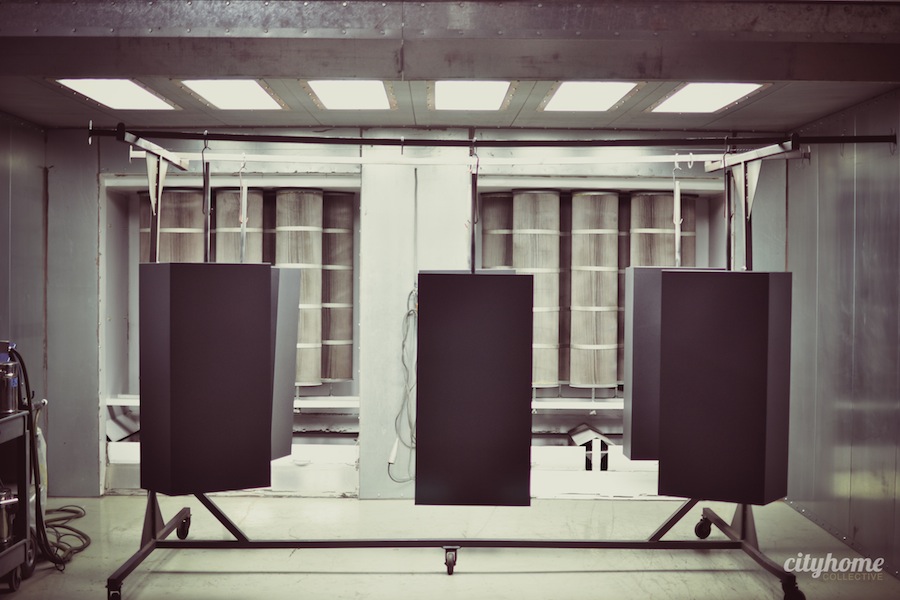

Powder Coating is the best method available for coating metal, which is one of the many reasons we utilize this process at Ore Inc. In short, it is a static electric process in which color, in a powder form, is charged and transferred onto the prepared metal which is then heated and cured in a sealed precision oven that emits no VOCs into the atmosphere and creates a sustainable, durable finish. We are proud to say that we intentionally designed and built our own powder coating system to retain full control of both quality and cleanliness. Powder coating is better than other low-VOC products in that it's NO VOC's (volatile organic compounds). During the preparation process, we capture all of our drain water. We dump nothing down the drain without first, under our own devices, testing and verifying that everything that goes down the drain is no more hazardous than a typical household drain. We don't do this because we are regulated to, but because this is how we choose to do it. We recycle 100% of all of our scrap metal.

All of our products qualify for LEED points in four categories: recycled content of raw material, non VOC finishes, non VOC sealants, FSC certified woods.